Electric melting magnesium aluminum spinel is a new type of high-purity refractory material made by melting high-purity alumina and lightly burned magnesium oxide in a certain ratio at high temperature in an electric arc furnace and cooling them.

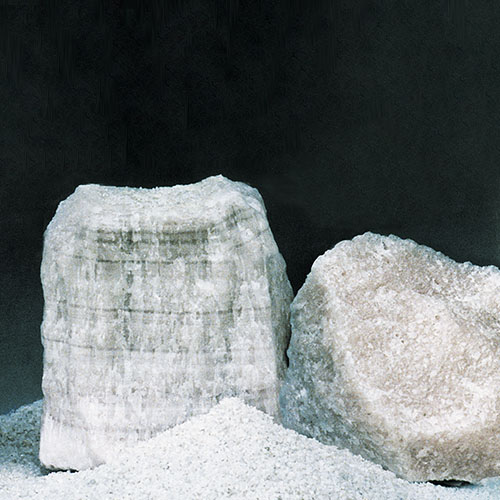

Magnesium aluminum spinel has a white color and excellent properties such as good crystallization, uniform structure, high bulk density, strong corrosion resistance, and high thermal shock stability. It is an outstanding refractory material in the corundum series. Our company can produce various types of segmented sand and fine powder of magnesia alumina spinel according to customer requirements.

Our company’s magnesium aluminum spinel has the following physical and chemical indicators:

| Item | Al2O3 | MgO | SiO2 | Fe2O3 | Bulk density B.D |

| Index | 70%-77% | 22%-28% | ≤0.6% | ≤0.4% | ≥ 3.2g/cm3 |